3D Printed Lenses Provide Sharper Ultrasound Images

By MedImaging International staff writers

Posted on 21 Dec 2016

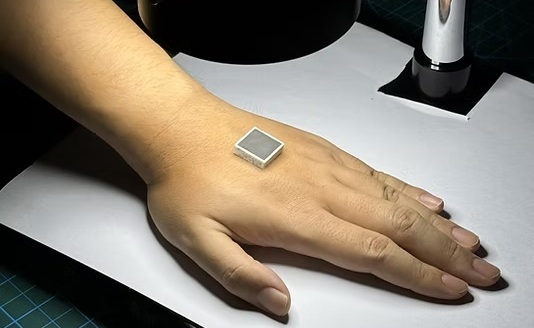

An innovative ultrasound probe is equipped with superior resin transducer lenses manufactured using three-dimensional (3D) printing technology.Posted on 21 Dec 2016

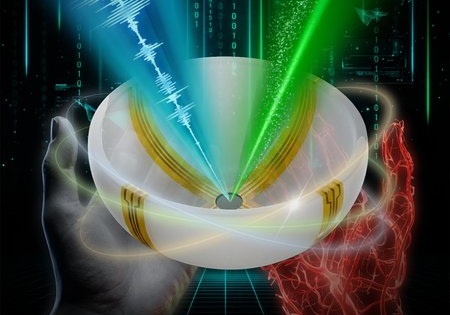

Developed by researchers at Nanyang Technological University (NTU; Singapore), the technology allows the printing of complex lens shapes for ultrasound probes that can be used to focus the resulting waves at multiple sites, or to shape waveforms with complex temporal and spatial shapes to a specific target. Current ultrasound design is limited by the optical characteristics of glass, which dictate cylindrical or spherical shaped lenses, thereby restricting the clarity of the imaging.

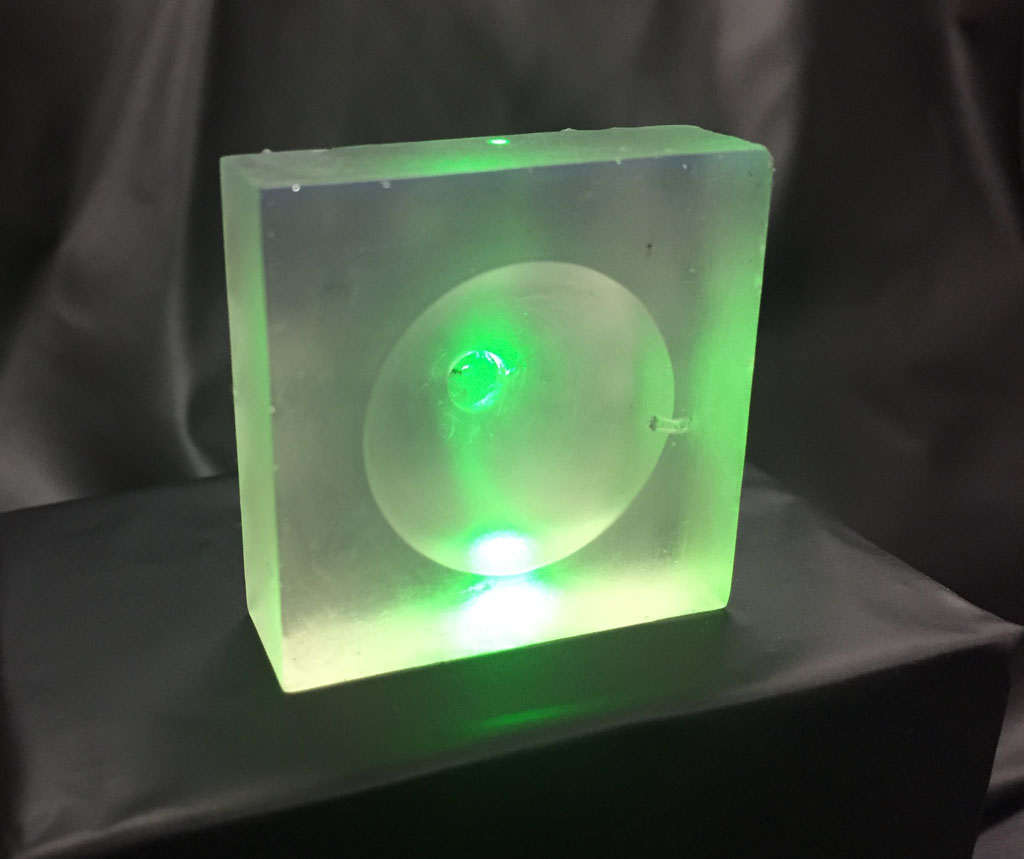

Image: A 3D printed resin lens for ultrasound overcomes the limitations of glass (Photo courtesy of NTU).

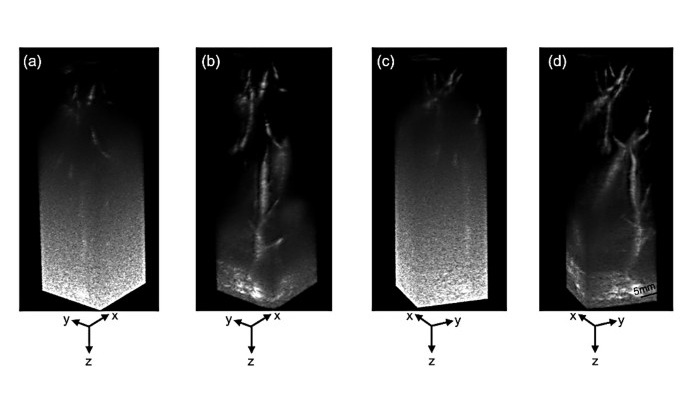

The arbitrarily shaped surfaces are made of polymers and printed with 3d printers, using three different polymer materials and a simplified deposition technique. The process involves painting layers of carbon-nanotube powder and polydimethylsiloxane. Together with a clear resin, pressure amplitudes of 300 bar peak positive can be obtained, and the flexibility of the polymer substrates allows complex waveforms to be generated. The study describing toe fabrication process and testing was published on October 29, 2016, in Applied Physics Letters.

“In most medical surgeries, precision and non-invasive diagnosis methods are crucial. This novel device not only determines the focus of the wave but also its shape, granting greater accuracy and control to medical practitioners,” said lead author Claus-Dieter Ohl, PhD, of the NTU School of Physical and Mathematical Sciences. “3D printing reinvents the manufacturing process, enabling the creation of unique and complex devices. In turn, the way medical devices are created needs to be rethought. This is an exciting discovery for the scientific community as it opens new doors for research and medical surgery.”

An ultrasonic probe consists of a piezoelectric element, backing material, an acoustic matching layer and an acoustic lens. The piezoelectric element generates the ultrasonic waves by repeatedly expanding and contracting; the backing material prevents excessive vibration in order to improve axial resolution; the acoustic matching layer improves impedance; and the acoustic lens prevents the ultrasonic waves from spreading and focuses them in the slice direction to improve the resolution.

Related Links:

Nanyang Technological University