3D Printed Plastics Could Replace Metallic Collimators

By MedImaging International staff writers

Posted on 18 Nov 2019

3D printing of plastic collimators for external beam radiation therapy (EBRT) could improve accuracy and reduce dose delivery and collimator manufacturing time, claims a new study.Posted on 18 Nov 2019

In order to develop the plastic collimators, researchers at Tomsk Polytechnic University (TPU; Russia), Moscow City Oncology Hospital No. 62 (Russia), and University Hospital Hamburg-Eppendorf (UKE; Germany) first used a numerical model to study the capability of high impact polystyrene (HIS) and acrylonitrile butadiene styrene (ABS) plastics to absorb an electron beam, and the required thickness and manufacturing method needed for the printed collimator to completely absorb the EBRT dose.

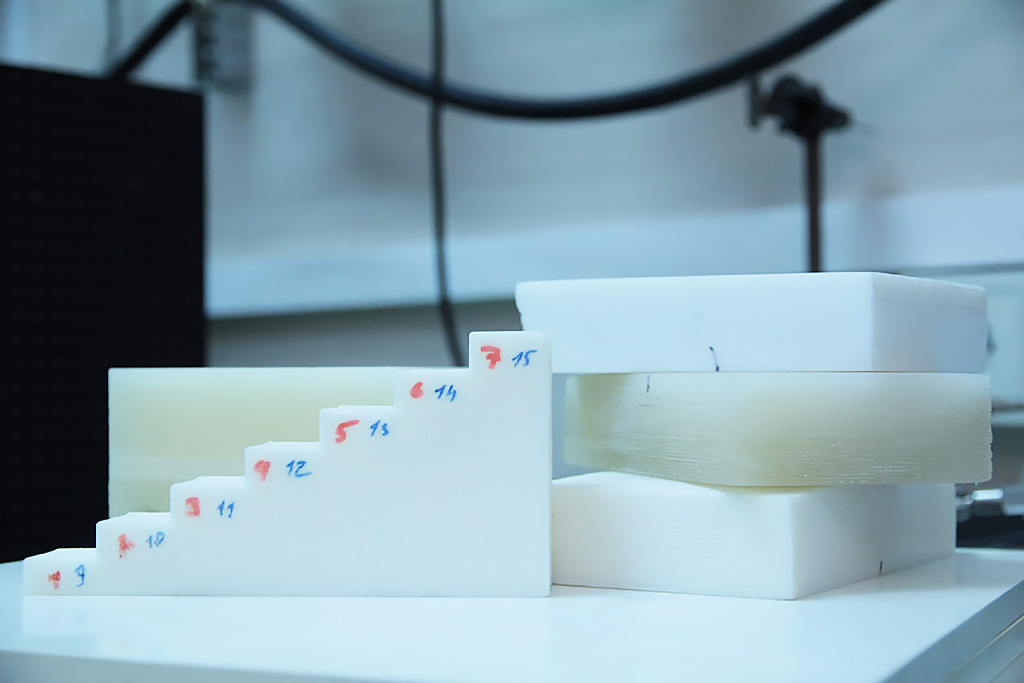

Image: Plastic collimator samples made using 3D printing (Photo courtesy of TPU)

They then used the plastics to manufacture the first products through the method of layer-by-layer fused deposition modeling, using rapid prototyping. As the manufacturing process can affect crucial properties, such as material homogeneity (due to the presence of residual air-filled cavities), Monte Carlo simulations were used to determine electron depth dose distribution. The appropriate thickness for total absorption of 6 MeV electron beams was found tobe at least 4 cm, at least 8 cm for 12 MeV, and 11 cm for 20 MeV. The study was published in the August 2019 issue of Physica Medica.

“Metal collimators should be 1.6 cm thick to absorb the beam but, unlike metal, plastic does not have the same density and a number of other characteristics. We conducted a number of calculations and experiments to determine the thickness of a plastic product,” said senior author Sergei Stuchebrov, PhD, of the TPU Research School of High-Energy Physics. “For instance, we used special dosimeters, placed inside the plastic, to measure the depth distribution of the electron beam. The results can be used to further develop 3D printing procedures for medical electron beam profile formation.”

Collimators allow radiotherapy treatment (RT) flexibility in shielding organs-at-risk (OAR), while ensuring that the prescribed dose is delivered to the target. While in linear RT, a multi-leaf collimator (MLC) can be used to align the treatment field parallel to the radiation field and to the shape of the tumor, EBRT works from multiple directions, requiring fabrication of a patient-specific collimator using hand-crafted blocks.

Related Links:

Tomsk Polytechnic University

Moscow City Oncology Hospital No. 62

University Hospital Hamburg-Eppendorf