New MRI Technology Provides a Third More Productivity

By MedImaging International staff writers

Posted on 05 Jan 2010

The combination of two different magnetic resonance imaging (MRI) technologies provide patient-centered care and significantly improves productivity across the entire MRI workflow.Posted on 05 Jan 2010

Siemens Healthcare (Erlangen, Germany) Tim (Total imaging matrix) technology and with its new Dot (Day optimizing throughput) engine were recently introduced in the new Magnetom Aera 1.5 Tesla and the new Magnetom Skyra 3T scanners at the 95th Scientific Assembly and annual meeting of the Radiological Society of North America (RSNA), which took place from November 29 to December 3, 2009, in Chicago, IL, USA. These two new scanners are the first to incorporate both Tim and Dot technology. Siemens will also demonstrate additional innovations, such as the Tim Dockable Table, for easy patient preparation outside the scanner room, and an all new coil architecture incorporating DirectConnect coil design, providing cableless coils for fast and easy set up and higher signal-to-noise ratio (SNR).

The Siemens-unique Tim technology was launched in 2003. Since then, more than 4,000 Tim systems have been sold. Tim 4G is the latest version of Tim and the most advanced generation of coil technology. After conventional and array technology, Siemens pioneered Integrated Panoramic Array technology in 1997 and the Tim technology in 2003. Tim 4G is now the 4th generation, offering ultra-high-density coils, DirectRF and other features for improved flexibility, accuracy, and speed. Tim 4G technology provides newly designed ultra-high density coils with an array of up to 204 coil elements that utilize up to 128 channels. As a result, the user will have enough channels to support imaging with ultra-high-density coils, excellent image quality with high signal-to-noise (SNR) is routine and high processing speed improves productivity even further. Additionally, without coil or patient repositioning the Tim coils allow covering the complete anatomy of the patient from whole body coverage (up to 205 cm) to smallest details.

Today's healthcare environment is increasingly faced with less staff, less reimbursement, less time. With this radiofrequency (RF) solution, Siemens was able to focus on the productivity, across the entire MRI workflow, and thus developed the Day optimizing throughput (Dot) engine. Dot multiplies the power of its Tim technology, resulting in greater image consistency, improved diagnostic confidence, greater ease of use, and increased productivity.

"We strive to be a part of the solution to the challenges in Healthcare today. Siemens is proud to welcome in a new era of MRI,” said Walter Märzendorfer, head of magnetic resonance, Siemens Healthcare. "Tim and Dot are the direct response to today's demanding world of healthcare economics. Together, they deliver faster, more efficient throughput for up to 30% more productivity per day.”

Tim has new patient-adaptive technology, enhancing image quality and acquisition speed, as well as raising productivity in everyday practice and provides a completely redesigned RF system and an all-new innovative coil architecture that packs more coil elements into a smaller space (up to 204 coil elements with 48 channels as standard configuration), unlocking the possibility of higher element configurations and higher SNR. The result is high-resolution imaging that holds up even when zooming in on multistation images. With up to 128 channels, Tim provides enough channels to utilize ultra-high density coils.

Tim enables increased resolution and a total field of view (FoV) of up to 205 cm with no coil or patient repositioning. With Tim, the most flexible parallel imaging is offered enabling simultaneous parallel acquisition in two directions for fast, high-resolution three-dimensional (3D) data in a breath hold and this is supported by inline multiplanar reconstruction (MPR) capabilities.

The DirectConnect coil design provides cable-less coils for fast and easy setup and higher SNR. For flexible coils, one-hand operation with SlideConnect makes patient set-up even easier. For superb coverage of the patient's anatomy, the Tim coils allow the user to select exams, not coils. Tim's coils can be integrated to support large anatomic coverage, for instance, combining head, neck, body, and spine coil elements to create a neurovascular array. Furthermore, the new coils are exceptionally lightweight (18-channel body coil of approximately 1 kg) and easy on the patient.

The new Tim Dockable Table comes with an integrated, removable spine 32-channel coil. It is completely Tim-compatible, with integrated DirectConnect and SlideConnect coil ports. Critically ill, physically challenged, bariatric patients and other immobile types of patients can be prepared outside the scanner room and wheeled in for the exam. The table holds up to 250 kg, even when mobile. For patient safety, handrails are integrated into the Tim Dockable table. It is easily docked to the magnet and allows faster exam set-up and higher patient throughput.

DirectRF, Tim's new all digital-in/digital-out design, integrates all RF transmit and receive components at the magnet, eliminating analog cables for true signal purity. This compact and efficient design enables an immediate feedback loop for real-time sequence adaptation.

TimTX TrueForm enables optimized RF transmission for excellent B1 homogeneity and scalability to higher numbers of transmit channels to empower new applications. Dot makes it easy to get the best possible results for virtually any type of patient, providing uniquely customized, optimized scans configurable to patient condition or clinical question. Dot proposes optimized exam strategies, requiring only confirmation prior to scanning. Dot adapts to each patient's breath-hold capacity and then links to the user's best scanning protocol to match. Personalized, high-quality exams can be easily reproduced, even when conditions change. Dot can also be customized easily to reflect the standards of care of each individual institution.

With intelligent automated workflows customized to your standards, scans are completed faster and more easily, with less chance of errors or repeats. Dot links proper protocols and procedures, so that the optimal FoV is instantly estimated. Furthermore, automated positioning and alignment of slices can provide fast and robust image quality across all patients. Dot also integrates AutoVoice Commands into the scan process, ensuring the synchronized timing of breathing and scanning, while lowering variability and stress for the MRI technologist.

Dot offers optimized engines for brain, cardiac, abdomen, knee, angiographic, and oncology exams. Both systems provide 70-cm open-bore design together with the innovations: Tim and Dot, thereby providing ease of use, and is designed to bring extra value across the entire imaging process. Tim supplies the power needed for excellent image quality, while Dot takes away the complexity inherent in MR scanning.

The 70-cm open-bore design of Magnetom Aera and Skyra can accommodate a large variety of patient sizes, shapes, and conditions. The friendly and open appearance helps to reduce sedation rates, minimizes stress for claustrophobic patients, and leads to higher throughput and more referrals. Moreover, the super-short magnets allow many studies to be completed with the patient's head outside the bore while still supporting a full 50-cm FoV (45 cm in z-direction).

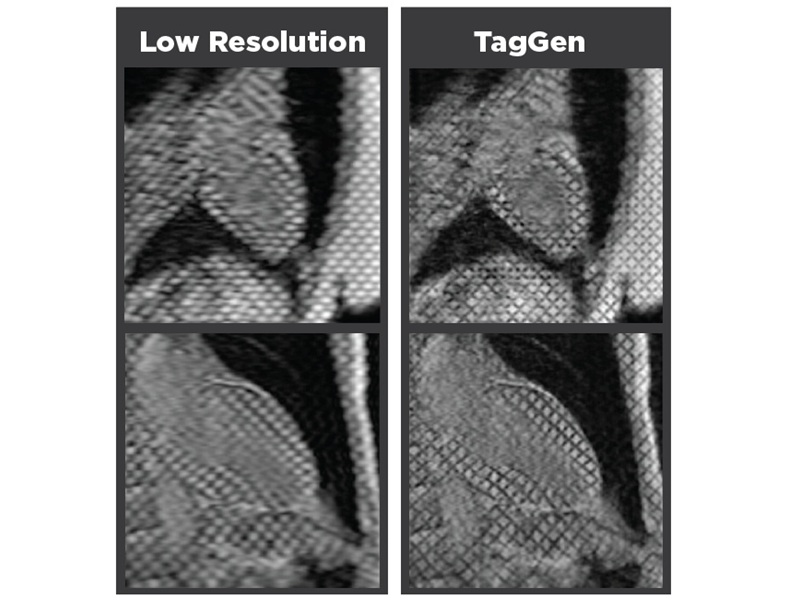

Tim's new ultra high-density array, with up to 204 coil elements combined with a new RF design with up to 128 RF channels, leads to an enormous SNR increase. This enables high-resolution imaging that holds up even when zooming in on multistation images.

The 3T Magnetom Skyra is also optimized with Siemens TimTX TrueForm design for excellent B1 homogeneity. Clear, sharp images can be viewed with 50% more imaging volume and TimTX TrueForm provides the foundation for multichannel transmit array capabilities at 3T.

In addition to Tim and Dot, both the Magentom Aera and Skyra come with Tim DirectConnect cableless coils and an optional Tim Dockable Table. The newly designed cover provides the illumination MoodLight, allowing the color of the front panel to be freely chosen.

With syngo.via imaging software, productivity in MR reading is increased by up to 50%. syngo.via sorts the images automatically, prepares the case, and every step is guided the way the user wants it. syngo.via uniquely integrates imaging modalities and information technology (IT), making it possible to access and share information anywhere. Protocol planning can now be done remotely and all the information needed is transferred to the scanner automatically. Tim and Dot together with syngo.via should dramatically increase productivity in MR by transforming the whole workflow from planning, scanning up to reading and result sharing.

Related Links:

Siemens Healthcare