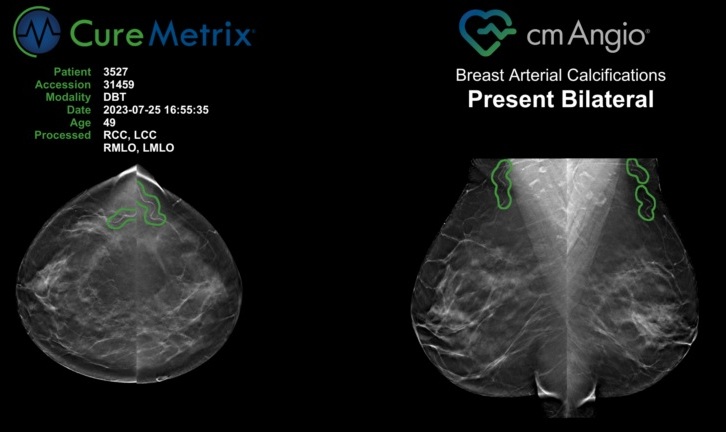

X-Ray Measuring Device Captures All Key Parameters in One Exposure

By MedImaging International staff writers

Posted on 24 Jun 2013

A new X-ray measuring device combines very high levels of accuracy with the intuitive operation of a touch screen. Posted on 24 Jun 2013

The device does not require any complicated menu settings—the sensor in simply connected to the base unit and the measurement is initiated; there is no need to select modes or ranges. While the orientation independent sensor captures all pertinent measuring parameters with a single exposure, the user-friendly slide-and-touch operation offers direct access to all required data such as dose, dose rate, kVp, half value layer (HVL), total filtration, exposure time, and pulses, including the corresponding waveforms.

Image: The RaySafe X2 measuring device (Photo courtesy of Unfors Raysafe).

Unfors RaySafe (formerly Unfors Instruments; Billdal, Sweden; Singapore), an international supplier of measurement systems for quality assurance of X-ray equipment, has launched its new RaySafe X2 measuring device, which comprises a base unit, an external sensor for radiofrequency (R/F) measurements, and a built-in mA sensor. When using both sensors, the device will display 12 parameters simultaneously. One simple swipe is all it takes to display parameter-specific waveforms.

The X2 R/F sensor, with its stacked sensor technology, prevents the influences of heel effects on the measurements. An innovative concept in sensor design and circuitry means that the RaySafe X2 provides dose rate sensitivity from 1 nGy/s for pulsed fluoroscopy and 50 nGy/s for continuous fluoroscopy. Because all exposures are saved in the base unit, measurement data remains available for reference and comparison purposes. The included X2 View software offers a variety of additional analyses and provides an Excel interface for simplified reporting.

“Our objective in developing the RaySafe X2 was to take quality assurance in diagnostic X-ray environments to the next level. The combination of an intuitive user interface and high-performance sensor technology not only simplifies the maintenance and functional checking of X-ray equipment but also reduces the likelihood of operator errors,” explained Mats Alm, vice president diagnostic X-ray at Unfors RaySafe. The RaySafe X2 saves service engineers and state inspectors valuable time while at the same minimizing the inspection-related downtime of the X-ray system.

RaySafe X2 has been available as a stand-alone system since January 2013.

Related Links:

Unfors RaySafe