AI Applications Predict Part Failures in Imaging Modalities

By MedImaging International staff writers

Posted on 23 Feb 2018

Machine data analytics company, Glassbeam, Inc. (Santa Clara, CA, USA) has built Artificial Intelligence (AI) applications powered by Machine Learning (ML) models for predicting part failures in expensive imaging modalities. The new applications delivered in real time through cloud-based dashboards and rules-based alerts are expected to change the way equipment maintenance is currently performed by in-house support staff at healthcare providers, independent service organizations (ISOs), and OEMs.Posted on 23 Feb 2018

Glassbeam is a machine data analytics company that focuses on bringing structure and meaning to complex data generated from any connected machine in the Industrial IoT industry. The company’s next generation cloud-based platform is designed to transform and analyze multi-structured data, delivering customer support and product intelligence solutions for its clients.

Presently, the replacement of an X-ray tube in a CT scanner is based on a number of ad hoc data inputs based on the age of the machine, number of scans performed, and image quality rendered, among other subjective factors. The lack of proper diagnostics of machine data signals results in several companies replacing tubes under the gun to ensure machine uptime at all costs. Glassbeam’s solution sends a warning signal to alert the facility about a week in advance of a potential tube failure. This makes the clinical engineering staff become proactive in avoiding unplanned downtime, saving costs, and averting patient re-scheduling at the last minute.

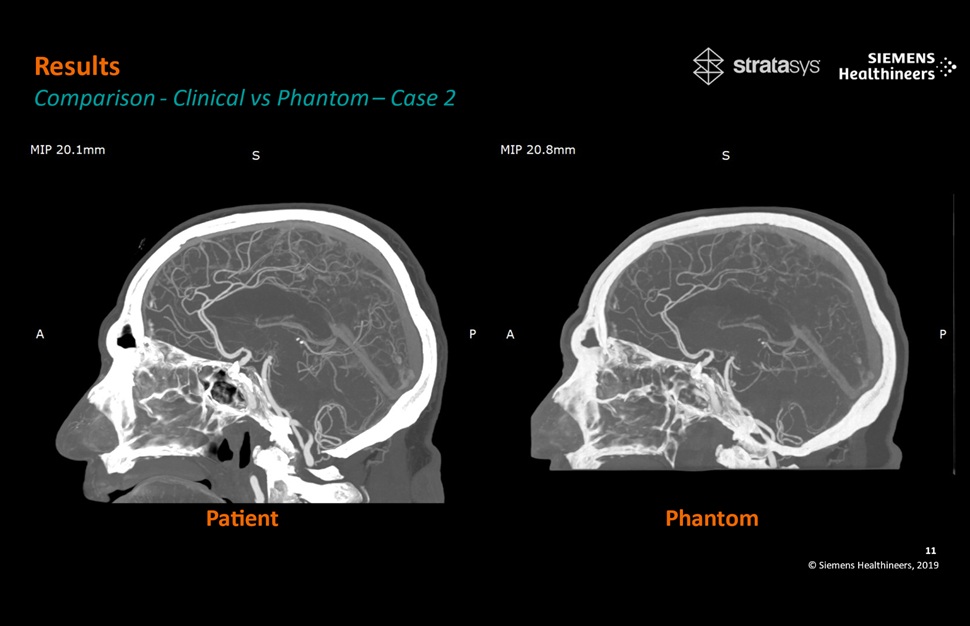

The first phase of these applications will focus on CT (Computed Tomography) Scanners that can cost anywhere between USD 1 million to USD 2.5 million or more, depending upon the desired image quality in procedures such as CT Angiography (CTA). Glassbeam plans to roll out new AI powered dashboards bundled into the current pricing model of its Clinical Engineering Analytics (CLEAN) IIoT blueprint.

"The management of medical machines such as MRI and CT Scanners has taken on a new level of complexity in recent years, due in part to the increased sophistication of equipment and ever-increasing requirements for compliance, safety, reliability and accuracy," said Corey Holtman, President at Gateway Diagnostic Imaging. "Predicting machine health and utilization patterns with help from latest techniques of Artificial Intelligence and Machine Learning is the next frontier to improve operations in Clinical Engineering function. I am pleased to see Glassbeam innovating on this exciting front for healthcare providers."

"The number of signals coming from connected machines in the IoT market has surpassed the ability for humans to keep track of them years ago," said Lise Getoor, Professor of Computer Science and Center Director of D3 (Data, Discovery and Decisions) initiative at University of California, Santa Cruz. "I am excited to see Glassbeam, as a supporting member of D3 Center, taking a leadership role in leveraging artificial intelligence to change the rules of the game for the healthcare market."

"The parts replacement industry for global installed base of medical imaging equipment in 2020 is slated to be a USD 3.6 billion market," said Puneet Pandit, Co-founder and CEO at Glassbeam. "With AI and ML applications based on analyzing millions of sensor readings captured in Glassbeam cloud each day, even with a modest 10% savings, we are ready to make a significant dent on the underlying inefficiencies of support operations, supply chain, parts and material logistics planning for large enterprises in the healthcare market."

Related Links:

Glassbeam

Guided Devices.jpg)