3D Models Improve Outcomes for Heart Surgery Patients

By MedImaging International staff writers

Posted on 11 Jul 2017

Researchers have shown that cardiologists could benefit from using patient-specific heart valve models while preparing for heart valve replacement surgery.Posted on 11 Jul 2017

The scientists used new 3D printing technologies and standard Computed Tomography (CT) scans to create patient-specific heart valve models.

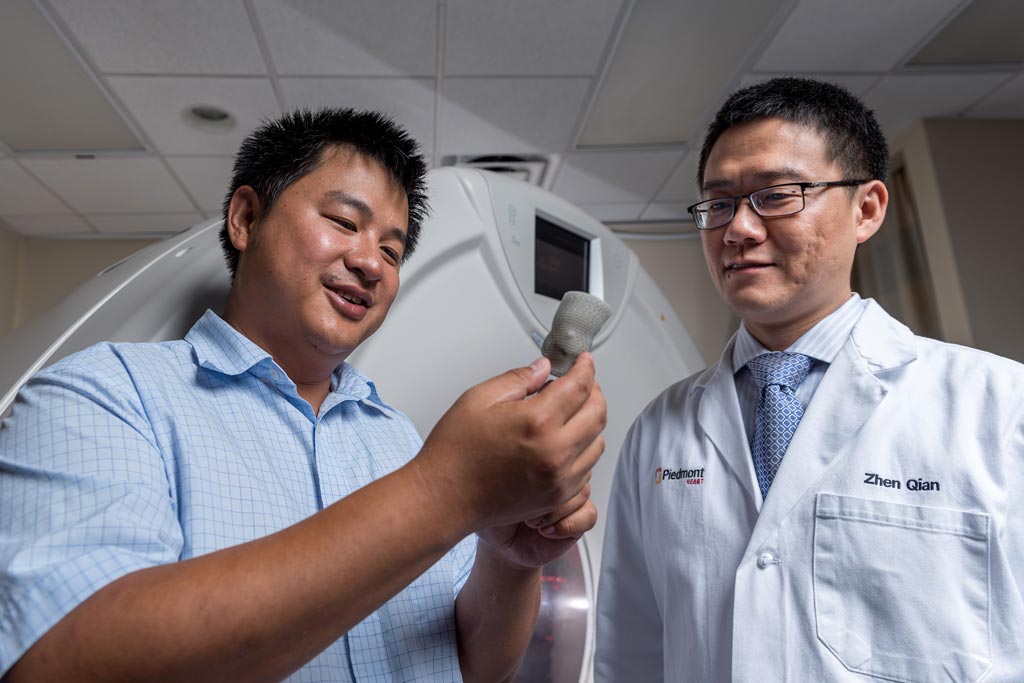

Image: Kan Wang, a postdoctoral researcher at Georgia Tech, and Zhen Qian, chief of cardiovascular imaging research at Piedmont Heart Institute, inspect a printed heart valve (Photo courtesy of Rob Felt, Georgia Tech).

The researchers from the Georgia Institute of Technology (Georgia Tech; Atlanta, GA; USA) and the Piedmont Heart Institute (Atlanta, GA, USA) intend to use the technology to increase the success rate of Transcatheter Aortic Valve Replacements (TAVR) procedures. The study was published in the July 3, 2017, issue of the journal JACC: Cardiovascular Imaging.

The researchers used CT imaging to scan 18 valve-replacement surgery patients, and created the models using a multi-material 3D printer. The researchers were able to recreate calcium deposition, aortic stenosis, and other patient-unique cardiac aspects.

The researchers found that the 3D-printed valves accurately mimicked the physiological qualities of the real heart valves and could help cardiologists reliably predict paravalvular leakage, and pick the best prosthetic valve.

Zhen Qian, chief of Cardiovascular Imaging Research at Piedmont Heart Institute, part of Piedmont Healthcare, said, "Paravalvular leakage is an extremely important indicator in how well the patient will do long term with their new valve. The idea was, now that we can make a patient-specific model with this tissue-mimicking 3D printing technology, we can test how the prosthetic valves interact with the 3D-printed models to learn whether we can predict leakage. Even though this valve replacement procedure is quite mature, there are still cases where picking a different size prosthetic or different manufacturer could improve the outcome, and 3D printing will be very helpful to determine which one. Eventually, once a patient has a CT scan, we could create a model, try different kinds of valves in there, and tell the physician which one might work best."

Related Links:

Georgia Institute of Technology

Piedmont Heart Institute